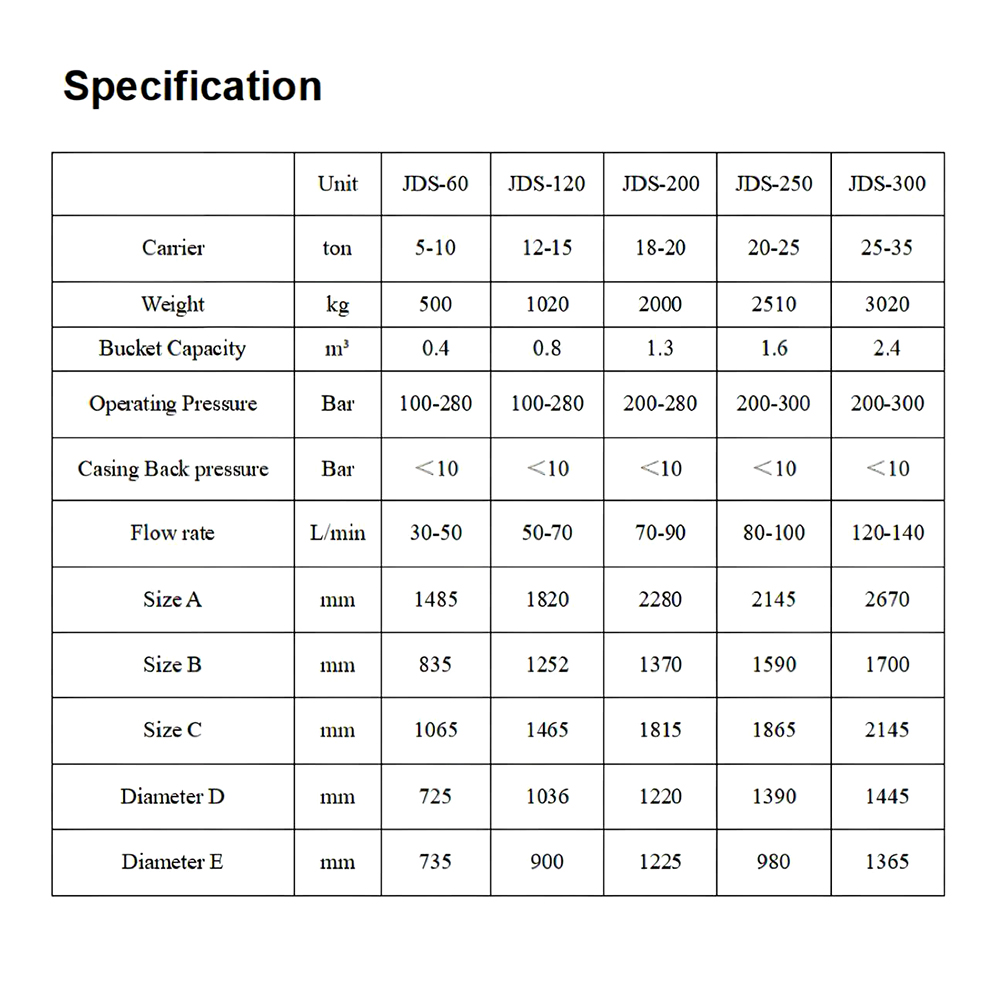

JDS-250 series SCREEN BUCKET

Engineered for in-situ material screening and recycling, eliminating trarhsport costs through closed-loop Applicable in municipal projects, such as road construction, pipeline backg, hydraulic engineering,aggregate classification. Construction mix screening, river gravel washing, Soil remediation beach reclamation , Horti cultural soil refining, Contaminated soil treatment.

Product description

PRODUCT ADVANTAGE

1.Site-Independent Operation.On-site screening and material utilization

eliminate transport costs.

2.Universal Excavator Compatibility. Fits 95% excavators with zero functional interference post-installation.

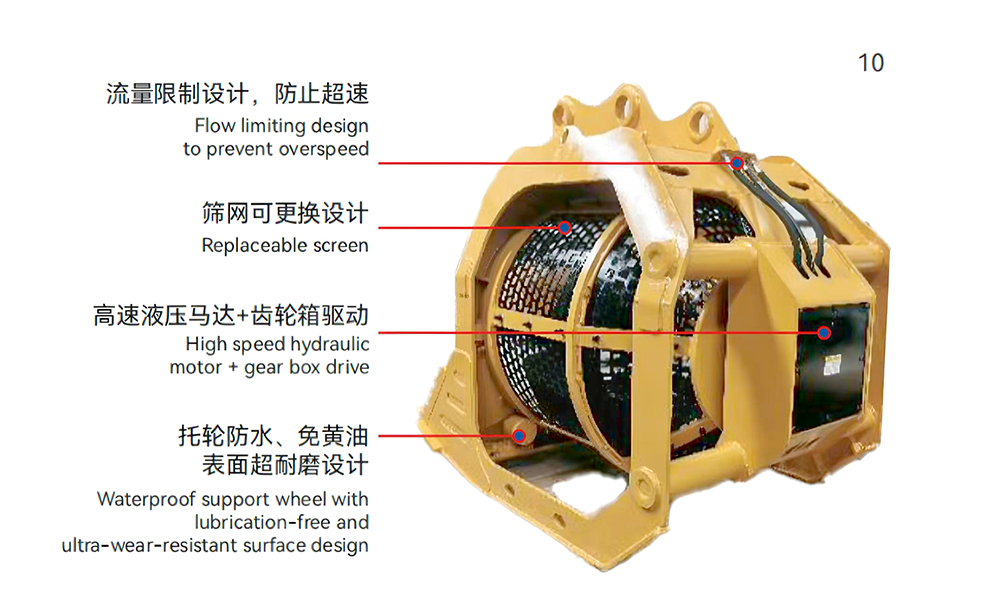

3.Dual-Drive Torque Amplification.High-pressure hydraulic motor + gearbox direct drive delivers 150% torque boost.

4.Hydraulic Safety Assurance.Integrated flow limiter prevents motor over speed damage.

5.Maintenance-Free Roller System. Specially engineered rollers (HB500):3X lifespan with sealed lubrication.

6.Modular Screen Customization.Customizable screen apertures(5-200mm),multi-configuration support per unit.

7.Rapid Screen Replacement.20-minute changeover without specialized tools.

8.Submersible Operation.IP68-rated waterproofing for operations in 1.5m water depth.

APPLICATION

1. Engineered for in-situ material screening and recycling, eliminating transport costs through closed-loop.

2. Applicable in municipal projects, such as road construction , pipeline backfilling , hydraulic engineering aggregate classification.

3. Construction mix screening, river gravel washing , Soil remediation, beach reclamation ,Horticultural soil refining ,Contaminated soil treatment.